Loop Chemicals

Local Ammonia Production, Global Impact

The Challenge

Ammonia is the world’s highest-volume commodity chemical and the foundation of modern fertilizer. Today, it is produced almost entirely using the fossil-fuel-based Haber-Bosch process, which accounts for roughly 2% of global greenhouse gas emissions. Because the process is only economical at massive scale, production is centralized in large facilities located far from farms, resulting in high transportation costs and supply chain inefficiencies.

Technology

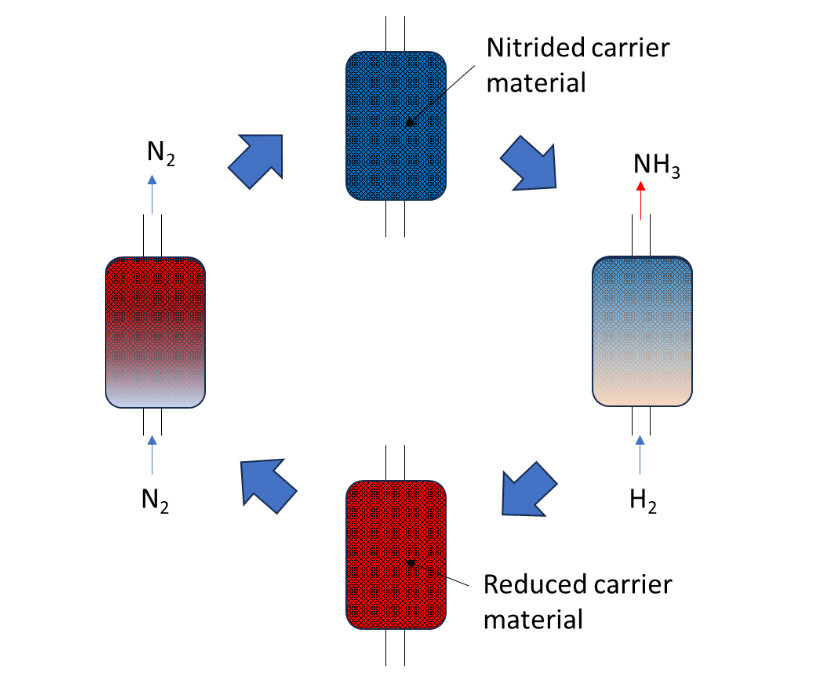

Our Chemical Looping Ammonia Synthesis (CLAS) technology produces ammonia using a recyclable carrier material in a looping cycle. Nitrogen and hydrogen are alternately reacted with the carrier, enabling ammonia synthesis under milder conditions than Haber-Bosch. This approach improves energy efficiency and makes smaller, modular production systems economically viable.

Impact

Improved Supply Chain Resilience

Distributed, local manufacturing reduces reliance on centralized production and long-distance transport.

Reduced Environmental Impact

CLAS enables the use of local clean energy sources and low-carbon feedstocks, significantly lowering emissions.

Reduced Costs

Producing ammonia near end users eliminates transportation costs that can rival the cost of manufacturing.

Our Partners

Who We Are

Former Chief Scientist at SABIC Agri-Nutrients; a major ammonia

manufacturer. Also, leader for SABIC’s Corporate Venturing arm in Boston.

Led SABIC Agri-Nutrient’s Market Development & Customer Technical

Support in the Americas. Also agronomist and family farmer of 600+ acres.

Veteran technologist from AgTech industry. Expertise in bringing new ag

technologies from lab to market.

Chemical engineer implementing the latest methods in materials

development and process design.

Partner With Us!

Please fill out the form to get in touch with us!